Leon McCaughan

Integrated Photonics Research Group

Department of Electrical & Computer Engineering

FERROELECTRIC THIN FILMS

Lithium niobate (LiNbO3) is one of a class of dielectrics (ferroelectrics) with a large and varied set of nonlinear optical properties. One of the over-arching goals of our group is to develop the optical analog to integrated circuit technology: i.e., growth and processing techniques that allow us to control the path of, and interaction between, data streams of photons.

Designer Precursors

Unlike with semiconductors, there currently is no method for growing high quality crystalline ferroelectric thin films that preserves all of their bulk properties.

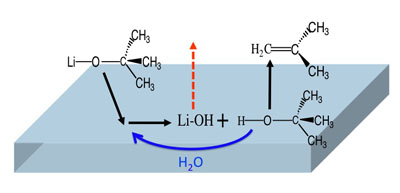

As a start, growth rates of thin films of these complex oxides are disappointingly low. Our studies of LiNbO3 using chemical beam epitaxy (CBE) show that the decomposition cycle of common alkoxide precursors of LiNbO3 is auto-catalytic: the precursor ligands generate water upon decomposition and this water, in turn, reacts further to form volatile monomers of Li and Nb that desorb from the surface, precluding high growth rates.

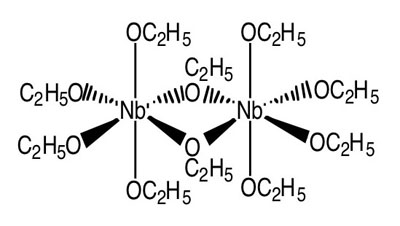

We are exploring precursors re-designed such that the ligands themselves no longer contain the elements of water, as well as engineering molecules that, on decomposing, remove the ligand intact from the growth surface before dehydration can take place. The first category of improved precursors includes those where ethoxy ligands are replaced by the chelating ligand dimethylaminoethanol, DMAE. The introduction of chelating ligands serves two purposes: 1) the DMAE ligand does not generate water upon decomposition, thus blocking the detrimental auto-catalytic cycle, and 2) the DMAE ligand may bind the central Nb atom at two positions, yielding monomeric species that are significantly more volatile than the currently used Nb2(OEt)10 dimer.

Patternable Ferroelectrics

Yet another challenge to the development of an integrated optic technology has arisen: the extreme chemical inertness of ferroelectrics severely limits the available suite of thin film processing tools for patterning structures such as waveguides and photonic crystals.

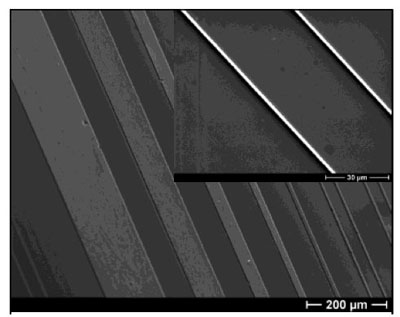

We have recently developed a technique which uses chemical vapor deposition (CVD) to deposit an amorphous LiNbO3 film on a LiNbO3 substrate. The film can be patterned using conventional photolithography and standard wet or dry etching techniques. The patterned film undergoes solid state regrowth to crystalline LiNbO3 when heated.